His Wheels First Children’s Story Coloring Book

Download and print off for your friends. If you would like to get copies of the Coloring Book, please contact us at info@hiswheels.org

How It All Started

A picture sparked HWI’s Hand-Pedaled Trike Division.”We need trikes throughout Africa” an international leader stated in 2005. Throughout the world many people live with lower extremity disabilities. Without transportation, these individuals are left crawling along on their hands, pulling their paralyzed limbs through the dirt and sewage. In hopes to combat such a sad truth, HWI’s Global Hand Pedaled Trike division has created an efficient alternative.

Trike History

In August 2005, three months after HWI began Alice Teisan met Kevin Nikolich at a party! Alice shared her impossible dream with Kevin, “I hope to take a welding class so I can build a hand-pedaled trike.” Within minutes Kevin said, “I’m a Mechanical Engineer. Can I design, build, and pay for the trike prototyping?”

Between 2005 and 2015 HWI’s team has designed 22 different trike prototypes and a trike manufacturing process. Here you can find a comprehensive trike history overview. Or if you prefer here is a brief trike history overview.

Trikes have been used for “Tools as Mission” as they have been assembled, fabricated, and manufactured on five continents.

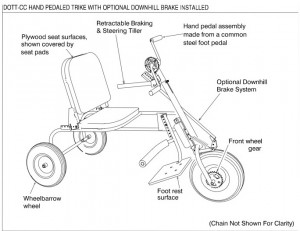

Construction

HWI Dual Offset Tube Trike (DOTT) is most easily built from round or square steel tubing, welded together. It uses relatively common, rugged bicycle parts for the drive train; and equally rugged sealed ball bearings and flat-free wheelbarrow wheels to avoid the spoke breakage and flat tire issues common on rough roads and paths. HWI uses plywood for seat surfaces, but thin steel, woven surfaces, or other seat surface options can be employed. This design can be modified to use different types of wheels, and suit local needs.

Ergonomics

The physical make-up of the DOTT was designed in order to provide the most efficient interaction between the trike and the rider. The DOTT’s seat design includes adjustability in the back angle, as well as the seat depth, leg length, knee angle and ankle position to properly fit the user. Crank arm length and gearing have been selected to help prevent elbow & shoulder joint strain. The offset frame tube design makes transfer from a chair or wheelchair easier. HWI has a Seating Manual available that was compiled by a licensed physical therapist.

FAQ (Trike DOTT Specific)

Here you will find answers to all the FAQ’s about why HWI did what we did on our DOTT trike design.

Multi-Disciplinary Approach

HWI has taken a multi-disciplinary approach to the research and development of our DOTT-CC trike. Our team has included engineers, nurses, orthopedic surgeons, general surgeons, physical and occupational therapists, kinesiologists, the end user, and others.

Kevin Nikolich is our chief engineer. Take a look at his portfolio.

Performance

The DOTT is highly maneuverable; it can nearly pivot around the rear wheels. The “direct drive” front wheel allows the trike to be pedaled in reverse for added maneuverability in tight situations. No active brake is provided for this reason as the hand pedals are used as the brake. The substitution of a coaster brake equipped front wheel (a 16” rear bike wheel) is recommended for hilly areas to provide better braking alternative on steep terrain.

A parking brake is available to prevent movement of the trike when the transferring in and out of the seat.

Cost

Costs will vary depending upon the availability of local parts, logistics and location. HWI estimates that the basic material costs will range from a low of $200 per trike or less; to a high of $350 per trike if most or all parts must be imported from the US, and all options are included and cost estimates do not include shipping.

At times HWI will send a one off trike with a potential partner. The DOTT-Compact Trike fits into two boxes that have gone as extra luggage with a person travelling by plane. Here are the specific box sizes and weights.

How Your Organization Can Build The DOTT Hand Pedaled Tricycle

HWI has developed and tested a manufacturing process that can make it possible for local organizations to build these trikes.

The Assembly Fixtures

These fixtures, along with a welder, tube bender, notcher, drill and various smaller tools are enough to equip a trike manufacturing shop for production. A reasonably experienced welder is recommended. All other production operations can be learned relatively quickly.

The goal is to provide the builder with a “turn-key” system for manufacturing the tricycle.

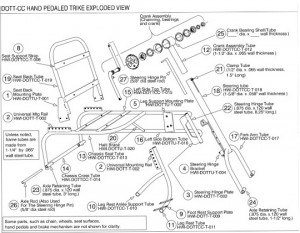

Drawings And Documentation

HWI can make many types of documents and drawings available to support trike production. Our trike plans are available for free to those with an interest in helping individuals with lower extremity disabilities in third world countries.

-

- Pictures

- Standard blueprints

- Exploded assembly views

- Individual part drawings

- Bill of material

- Parts sources

- Fitting manual

- Illustrated assembly manual (without manufacturing fixtures)

[wpdm_file id=3] [wpdm_file id=4] [wpdm_file id=5] [wpdm_file id=6]

If desired, a highly detailed 3D AutoCad model of the trike is also available.

Production Training

HWI has conducted some training programs in the Chicagoland area.

Prototypes

Between 2005 and 2015 HWI’s team has designed 22 different trike prototypes and a trike manufacturing process. Here you can find our comprehensive trike history overview. Or if you prefer here is a brief trike history overview.

Research & Development

HWI continues doing ongoing trike research and development.

Trike Community

We are working on building a place for the larger international trike community. Here you will find a variety of trike related topics covered.

University Trike Consortium

As we continue forward, through a culture of innovation we are building a university trike consortium. Our objective is to mine creativity among students across the country and around the world. Through our trike project we want to help students discover ways they can use their talents and professional training to impact the lives of those less fortunate while using their skills as a tool for missions. We have had students do projects and internships with us in the field of Kinesiology from the University of Illinois, Chicago (IL), Communications and Christian Formation and Ministry from Wheaton College (IL), Journalism from Roosevelt University (IL), Business from Spring Arbor University (MI), Vocational training from Immanuel Coe Technical School in Hyderabad, India, and Engineering from Messiah College (PA).

We are in communication with other universities and different partnerships throughout the country and around the world to help move our trike project forward. We believe there is a place for students in every discipline to take part in furthering our trike program. We welcome students, faculty, and others to contact us about working with us.

3 Responses to Hand-Pedaled Trikes